Lessons learnt from WE* resiliency projectSponsored

Without a robust power supply, essential facilities might not operate following a significant seismic event. With around 20,000 earthquakes in New Zealand each year (GNS Science, 2018), and the likelihood of a significant seismic event occurring in the future, the seismic strengthening of Wellington Electricity’s substation buildings is paramount to ensuring essential facilities can continue to operate during and after such an event. Jacobs provided detailed seismic assessments and seismic retrofit designs for more than 60 existing critical substation buildings.

To enhance the resiliency of power supplies across the Wellington region, Wellington Electricity (WE*) has completed seismic strengthening design on a portfolio of projects (the Wellington Electricity Earthquake Readiness Project) to upgrade the power distribution facilities to support the region's earthquake readiness and resiliency programme. Having been involved in the project since its early development in 2012, Jacobs’ structural and geotechnical teams in New Zealand have provided WE* with detailed seismic assessments and seismic retrofit designs for more than 60 existing critical substation buildings.

This article highlights Jacobs’ experience, challenges, and lessons learnt throughout the project’s key stages: seismic assessment, strengthening design, and construction.

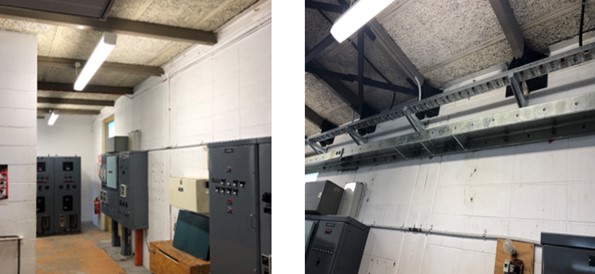

Figure 1 below shows one of the substations before (left) and after (right) roof-wall structure strengthening works.

Figure 1. Roof strengthening design Inside Brown Owl Zone substation (WE*, 2019)

Project challenges

Most of the existing substation buildings were constructed more than 50 to 60 years ago when building codes, material standards, and construction practices were less developed, especially concerning seismic demands. As such, these existing buildings are vulnerable to damage during a significant seismic event.

The seismic assessments found that the substation buildings had a critical structural weakness on their main components (ie members and connections), the construction material used (ie unreinforced-masonry) was below strength, the soil foundation had a risk of seismic liquefaction, and there was seismic irregularity of the layout. All of which made developing a resilient, practical, and strengthened design very challenging.

Furthermore, access during construction was limited because of the constraints imposed by the existing equipment layout.

Table 1 below summarises the key challenges of the project.

|

Types |

Challenges |

Specific Issues |

|---|---|---|

|

Due to inherent nature of the buildings and the site conditions |

Limited available information |

As-built information such as drawings, reports, material properties and construction specifications were often not available, therefore instructive site investigations were required to validate the existing structural design. |

|

Existing construction material |

Unreinforced masonry with low material strength and with inherent vulnerability to significant damage – due to limited knowledge and research of design and construction technology, primitive construction practice and methodology, and the less stringent provisions in the design and material standards at the period when the building was designed and constructed. |

|

|

Old buildings |

Designed and constructed according to superseded building codes and standards which are below the capacity required by the current codes and standards for new building. |

|

|

Low structural capacities (% NBS) |

The substation buildings varied significantly in nature, with almost every substation building unique in some way. Complex and seismically irregular systems, no redundancies, discontinuities of load path and low capacities (% NBS) of their components were common structural issues. |

|

|

Geotechnical hazards – a desk study |

A large proportion of the substations were built in the 1950s and 1960s, when there was only limited consideration of geotechnical hazards. The desktop study identified that liquefaction was the predominant geotechnical hazard, along with slope stability, depending on the position of the building within the surrounding landscape. There are numerous active faults trending north-south through the Wellington region that could cause severe ground shaking and liquefaction, and potential damage to building structures. |

|

|

Equipment layout |

The existing arrangement of the equipment, which was live and operational, was not practical to be altered, which caused a significant constraint in strengthening design and access during construction. |

|

|

Due to project requirements |

Functional requirements (Post-disaster/Essential facilities) |

Under the current New Zealand Building Code, substation buildings are classified as Importance Level 4 (IL4) essential facilities with post-disaster functions. This means they must provide continuous operation following catastrophic natural events (eg earthquakes, hurricanes, floods, etc). |

|

Target strength (% NBS) |

The brief was to strengthen the buildings to over 67% New Building Standards (NBS), which was very stringent considering the building’s inherent structural deficiencies.

|

|

|

Stakeholder collaboration |

The project had multiple stakeholders including local authorities, neighbouring private properties, utility owners, building consent officers and contractors, often with conflicting interests that required close coordination and perseverance of project personnel for the duration of the project. |

|

|

Safety in design |

The requirement for continuous operation of the substations created a significant hazard. The safety of the construction workers and design team, who could be directly exposed to live electro-mechanical high-voltage equipment, was paramount.

In response, the team reduced the amount of work required inside the substations as far as possible, exploring and applying non-traditional and innovative engineering solutions and construction materials.

Construction details had to be thoroughly thought out to ensure efficient constructability and avoid prolonged exposure of workers to these risks. Only contractors experienced in this type of work were used and they were often asked to participate in design meetings to help ensure the safest possible strengthening solution.

For example, highly pressurised sprayed concrete and fibre-reinforced concrete and steel frames were used dominantly outside the building, with minimal intervention inside.

|

Table 1 Challenges and issues with upgrading substation buildings

Lessons learnt

Holistic Methodology – balancing cost, programme and long-term performance

The overall cost of delivering engineering projects is subject to several variables, including project-specific requirements, complexity, design approach, construction methodology to be adopted, etc. To achieve the best possible outcome on this large and complex project, it was essential to be strategic in our decision-making, keeping the programme’s objectives in mind.

For example, we provided input into the importance level (IL4 or IL3) appropriate for each existing substation with respect to each condition (ie soil type, criticality, vulnerability, etc). Considering what the client specified for all substations, and applying Jacobs’ experience in seismic strengthening, we could recommend the appropriate IL to be used, while optimising project value and delivering an economically feasible solution.

Furthermore, understanding the client's business and broader project objectives is crucial to providing the right advice during design and project delivery. Jacobs worked closely with WE* to fully understand its resiliency programme and the funding of the project, which WE* had secured and wanted to complete within two years of commencing it.

To support this programme, Jacobs developed a process for early identification and management of geotechnical hazards to balance seismic performance importance level (ie IL3 vs. IL4) and the cost/programme to deliver a site-specific investigation.

Critical facilities with post-disaster functions are required to be designed for IL4 performance. However, for existing buildings, achieving IL4 performance is not straightforward, particularly if the geotechnical condition cannot meet the required performance level. In this case, we were able to lower the performance to IL3.

The principal characteristics of the process chart are set out below:

- IL4 adopted where geotechnical desktop study indicated a low risk of geotechnical hazards

- site-specific ground investigations would be considered when medium- or high-risk hazards were identified in the geotechnical desk study

- zone substations warranted a comprehensive ground investigation due to the criticality of the performance to the wider network

- GNS Science – a New Zealand state-owned institution involved in scientific research and providing advice and information related to geology, geophysics, seismology, and volcanology, in particular the seismic hazards in New Zealand – was consulted to confirm which sites were located on or near active faults, irrespective of the nature or criticality of the substation. Figure 2 shows the fault rupture zone below or very near to three substations in the Porirua Basin.

Figure 2. Ohariu Fault Rupture Zone (GNS Science, 2015)

A timely and efficient geotechnical process for screening a large number of sites

Jacobs recommended a single geotechnical desktop study covering all 91 sites with the findings presented in an individual summary schedule, and a covering report setting out the methodology and assessment criteria. The table's structure and content provided a quick and simplified summary to WE*, the structural engineer, and other stakeholders, facilitating early decision-making and advancement of the preliminary seismic assessments.

This early-stage desktop study was crucial in providing critical information and recommendations to our structural engineers and WE*.

Close coordination between geotechnical and structural engineers

In highly demanding and complex projects like the WE* resiliency project, working closely with the client, the core design team and the contractor creates an opportunity for the whole project team to resolve uncertainties and clear up any miscommunication and identify and address any other challenges.

Throughout the project, the geotechnical and structural engineers worked together very closely to understand how the critical interactions between geotechnical site conditions and structures impacted the building's seismic performance. In places with high seismic risk, geotechnical considerations had the potential to govern the % NBS score and required significant and costly solutions. Attention was given to the principal risks associated with geotechnical step-change phenomena, including liquefaction, slope stability, lateral spreading, and fault rupture.

Jacobs' engineers worked closely with the client to ensure that the strengthened buildings' seismic performance met their expectations in the most cost-effective way and with minimal disruption.

Designing beyond code – new ways of thinking

The most widely adopted and commonly used method of structural design for new builds is called code-based design. However, this approach is not enough for existing buildings, or sometimes not appropriate to solve the engineering problems specific to that existing condition. Design engineers should adopt an alternate design approach – one which follows the code but uses alternative ways of thinking to solve problems – designing beyond code.

Furthermore, buildings and other structures can be subjected to severe natural events wherever they are located. Some locations are inherently exposed to extreme environmental risks or located at areas prone to natural disasters (eg hurricanes, earthquakes, flooding, and erosion). New Zealand is in the Pacific ring of fire, a highly seismic-prone area with erosion and liquefaction as common hazards for the built environment. Each time a significant seismic event occurs, design professionals are reminded that building and essential infrastructure design must be carried out in strict accordance with code requirements, and even exceeding code requirements wherever appropriate.

Old buildings are challenging to retrofit due to the inherent vulnerability of construction material used, the structural system's complex irregularity, and the risks associated with seismic-geotechnical hazards. The solutions adopted during this project needed to be flexible: if they did not suit the existing site conditions, they could be modified efficiently without extensive redesign work. This required out-of-the-box thinking to develop practical solutions that addressed both these challenges, and the very stringent requirements of the current building codes and standards.

For the WE* resiliency project, Jacobs adopted a bespoke solution and methodology outside traditional engineering project delivery. Some of the engineering problems could not be addressed by the conventional methods recommended by the standards and current practice. Hence, designing beyond code and outside standard practice was necessary to provide engineering solutions to achieve the best outcome. For example, some of the buildings with little available information (ie drawings, material properties, etc) prompted multiple intrusive testing to validate assumptions and required engineers to be innovative in structural design.

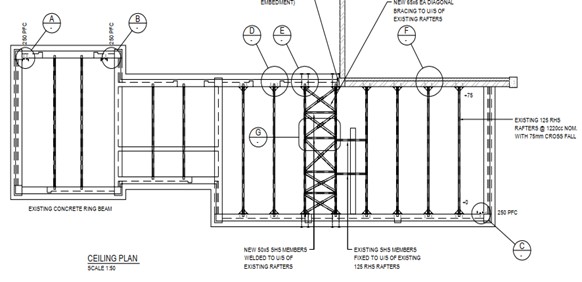

Figure 3 & 4 below shows an innovative solution for the roof strengthening of the Brown Owl substation, which used a rigid truss diaphragm system for seismic-resistant design.

Figure 3. Drawing of Brown Owl substation roof strengthening design (WE*, 2019)

Resiliency & adaptability – long term & high-performance

The recent Christchurch and Kaikoura earthquakes have shown us the overwhelming damage earthquakes can cause to infrastructure. In addition to the devastating loss of life, earthquakes can also have a catastrophic and widespread impact on the future of New Zealand’s economy, policies and way of life.

Although buildings and other structures are designed to code-prescribed loads within their intended service life (eg 50 to 100 years or more), these prescribed forces can be exceeded several times by the actual seismic acceleration forces during strong earthquakes, as proven by our experience with the recent Christchurch and Kaikoura earthquakes.

A new way of thinking to design a resilient, high-performance structure such as installing new anchors at the Tawa Zone substation shown in Figure 4 is the ultimate challenge for stakeholders. The recent earthquake events in New Zealand and other parts of the world have called for more robust, disaster-resilient and adaptable buildings and infrastructure. Designing with resiliency and adaptability in mind can achieve long-term, disaster-resilient, and versatile essential facilities.

This project allowed Jacobs to apply our experience from recent earthquakes, adopt the latest engineering practice and research recommendations to reduce the risk for earthquake damage, and provide resilient and long-term solutions for WE*.

Figure 4. Tawa Zone substation during construction showing new anchors on masonry walls (WE*, 2019)

Conclusion & project outcomes

Essential facilities like power, water, and hospitals, among others, are vital for society to function routinely and during emergencies. The need for resilient and adaptable facilities that can withstand extreme forces from natural disasters and continue to operate during emergencies makes them critical compared to other non-essential facilities.

To achieve the WE* resiliency project’s goals, Jacobs had to apply a strategic and unique methodology of project delivery, involving strategic client consultations, bespoke engineering solutions, and holistic consideration of every possible challenge, constraint, and issue. Designing with resiliency and adaptability in mind was a key driver in achieving a long-term and high-performance substation building.

Jacobs had to rely on their expertise in seismic design and exercise creativity to develop innovative and effective engineering solutions, which resulted in the following project outcomes:

- achieved the project target programme of delivery

- increased long-term resiliency of power supply

- enhanced seismic performance of the buildings

- ensured continuous operation during construction

- financial savings of the overall project due to collaborative design techniques

- no record of incidents and accidents during construction

- enhanced WE* operational capability and decision-making processes due to technical information resulting from the project

By Juvenal Verano & Jerry Spinks, Jacobs, New Zealand